Why is my foam latex shriveling up when demolding?

I have been working on an Art the Clown foam latex prosthetic lately. I have a positive ultracal lifecast of my face, and a negative ultracal shell mold of my sculpted Art the Clown face. I seem to have gotten the mixing process down pat, so i don’t think it’s a problem with that part. Just in case, my process is as follows:

-Speed 1, 30 sec: mix initial ingredients

-Speed 5 (max), 10 min: whip air into mixture to form merengue-like consistency

-Speed 2, 3 min: de-ammonize and refine

-Speed 1, 30 sec: add gelling agent

-Speed 1, 1 min: incorporate gelling agent

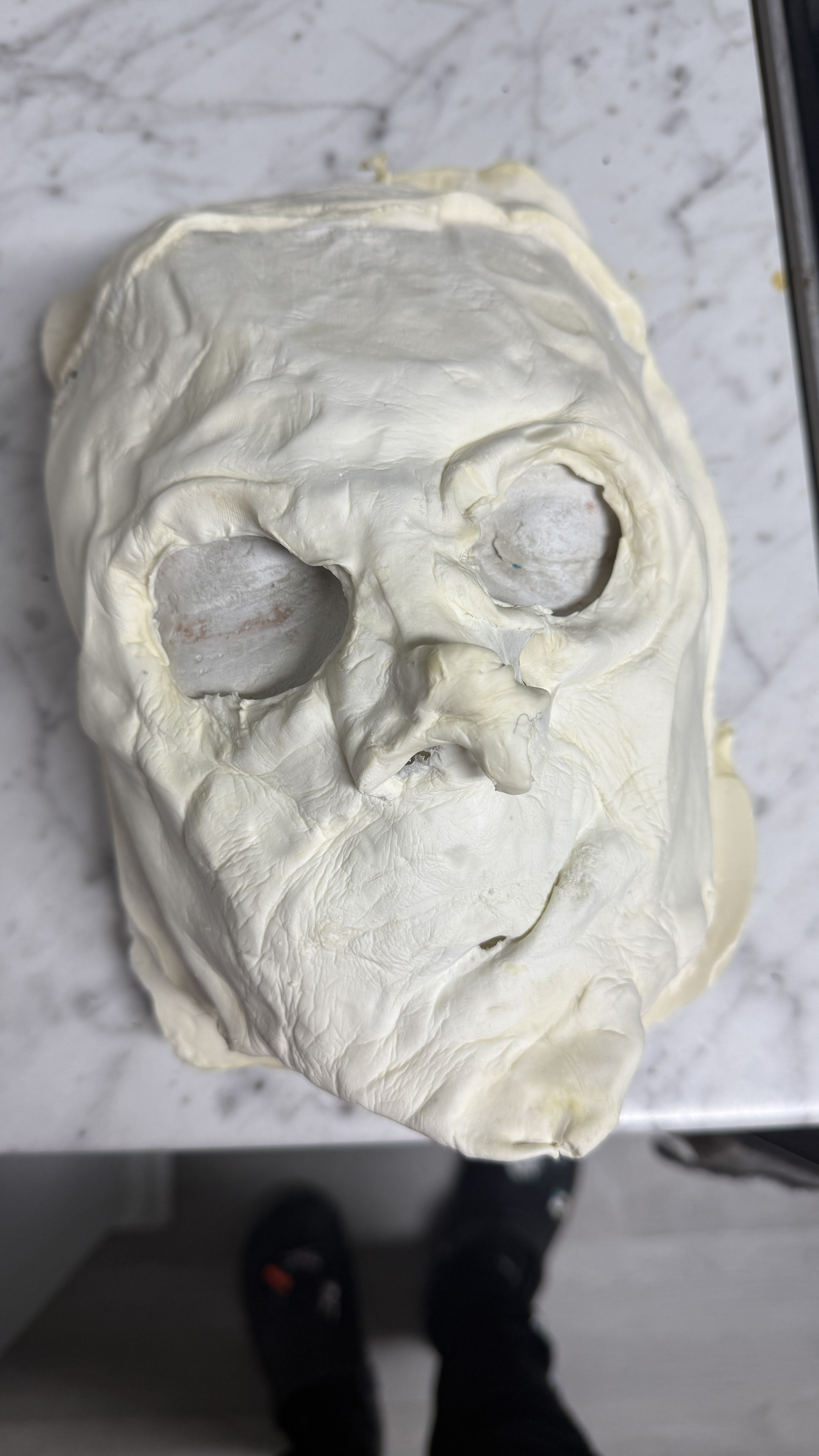

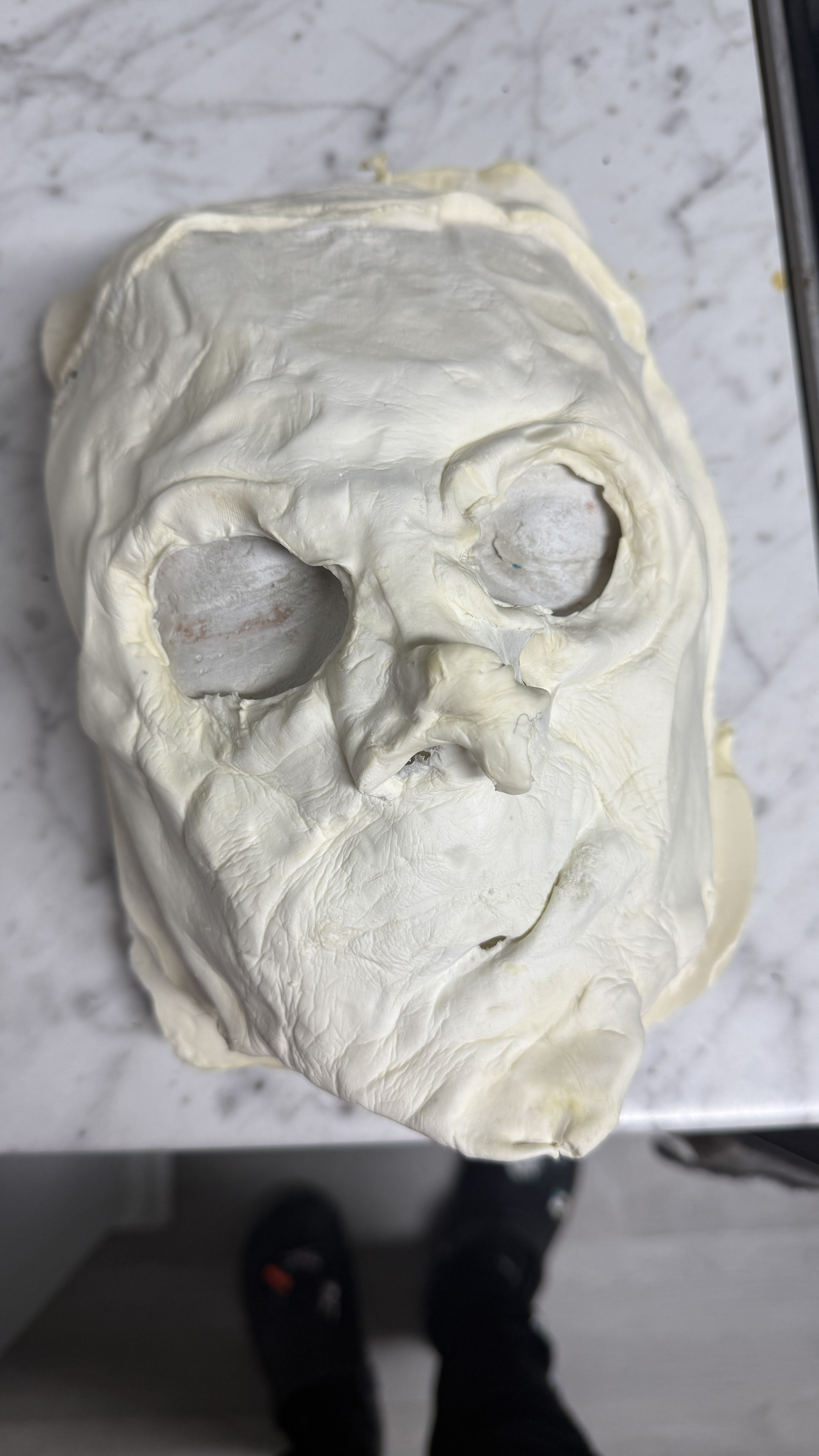

Then, i high-pour into the negative shell mold, use a chip brush to get it into the nooks and crannies, place the positive mold in, and clamp down with wood and strap. I let it gel for around 20 minutes, until it has a soft spongy texture (i test the texture with the overflown latex. when depressed, it doesn’t bounce back into the original shape). After that, i put it in the oven for 2 hours at 170 degrees fahrenheit. When i took it out, the spongy texture now bounces back elastically into its original shape. I then immediately demold while it’s still warm. However, when i remove the prosthetic from the mold, the whole thing shrivels up and seems to collapse in on itself. The texture is super soft and nice, and it stretches extremely well, so it doesn’t seem like the mixing went wrong. I think it might have something to do with the gelling period, or the baking period. The only obvious mistake that jumps out at me was the fact that i removed the strap and wood before putting the whole thing in the oven, so i thought the foam might be shifting and expanding around inside the mold, leading to this effect. The first photo below is from my initial results after demolding.

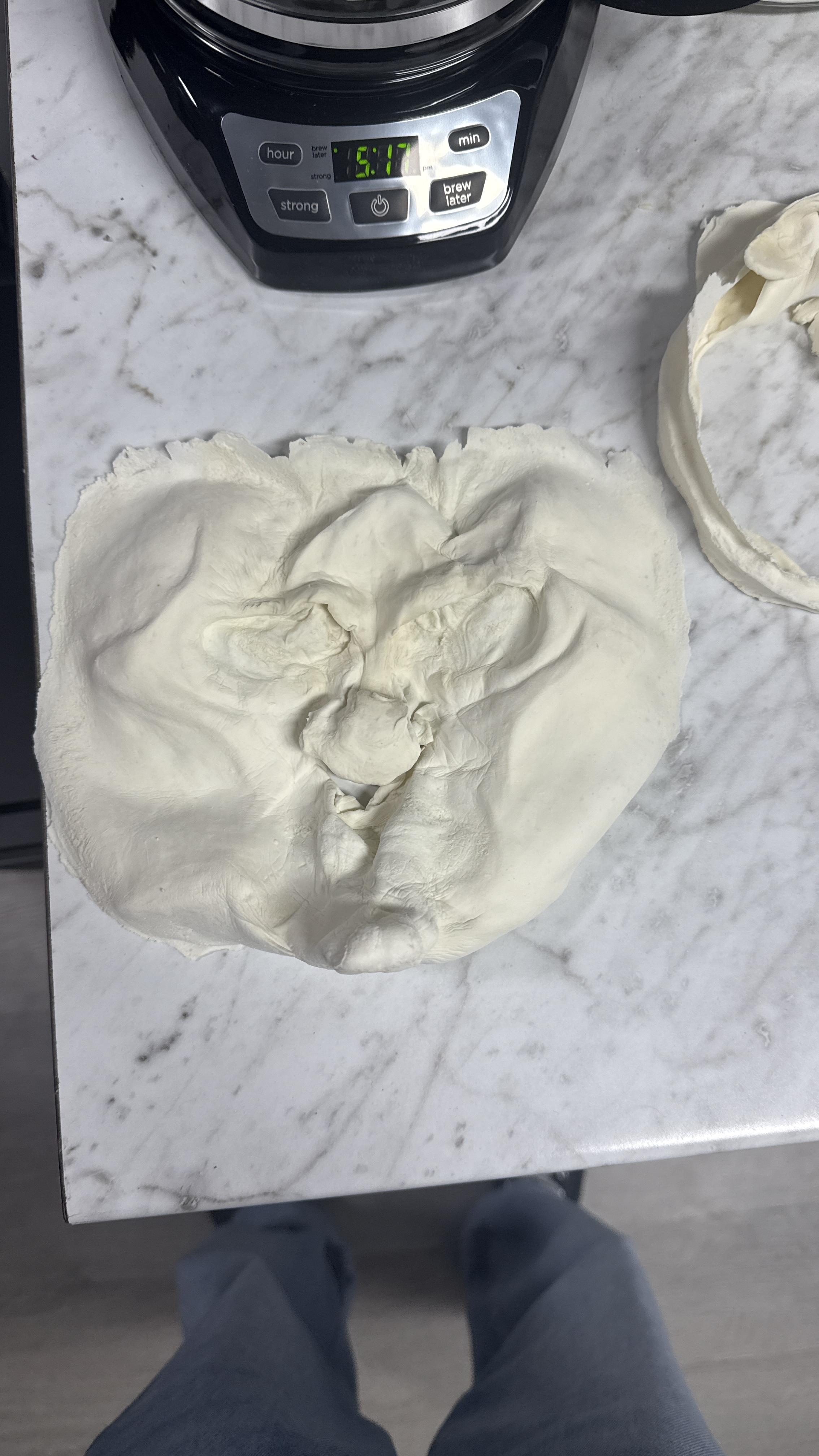

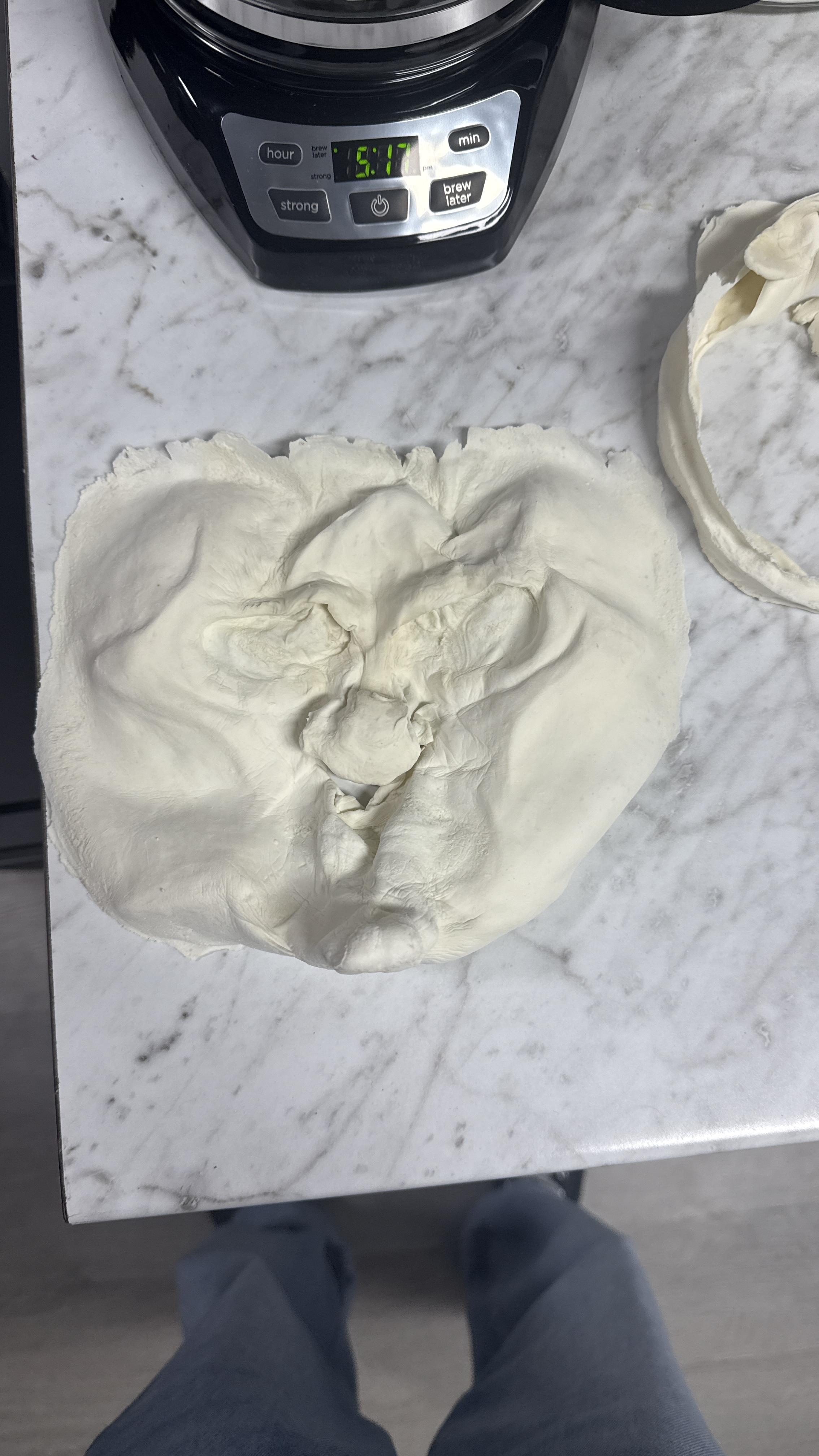

I tried the exact same process again. The only differences I made was the fact that i let it gel for around an hour, and then i put it in the oven with the strap and wood still secure. I put it in the oven for 2 hours at 170 degrees. When that was done, i rotated it 180 degrees horizontally to more evenly heat the whole thing. I left it in there for around 30-45 mins more. When i took it out, all of the overflown latex was very soft and elastic. However, when i demolded it, it shriveled up again. The second photo is from my second attempt. What is going wrong here? I only have enough materials for 1 or 2 more runs, so i want to try and nip this in the bud. Any tips? Photos below:

-Speed 1, 30 sec: mix initial ingredients

-Speed 5 (max), 10 min: whip air into mixture to form merengue-like consistency

-Speed 2, 3 min: de-ammonize and refine

-Speed 1, 30 sec: add gelling agent

-Speed 1, 1 min: incorporate gelling agent

Then, i high-pour into the negative shell mold, use a chip brush to get it into the nooks and crannies, place the positive mold in, and clamp down with wood and strap. I let it gel for around 20 minutes, until it has a soft spongy texture (i test the texture with the overflown latex. when depressed, it doesn’t bounce back into the original shape). After that, i put it in the oven for 2 hours at 170 degrees fahrenheit. When i took it out, the spongy texture now bounces back elastically into its original shape. I then immediately demold while it’s still warm. However, when i remove the prosthetic from the mold, the whole thing shrivels up and seems to collapse in on itself. The texture is super soft and nice, and it stretches extremely well, so it doesn’t seem like the mixing went wrong. I think it might have something to do with the gelling period, or the baking period. The only obvious mistake that jumps out at me was the fact that i removed the strap and wood before putting the whole thing in the oven, so i thought the foam might be shifting and expanding around inside the mold, leading to this effect. The first photo below is from my initial results after demolding.

I tried the exact same process again. The only differences I made was the fact that i let it gel for around an hour, and then i put it in the oven with the strap and wood still secure. I put it in the oven for 2 hours at 170 degrees. When that was done, i rotated it 180 degrees horizontally to more evenly heat the whole thing. I left it in there for around 30-45 mins more. When i took it out, all of the overflown latex was very soft and elastic. However, when i demolded it, it shriveled up again. The second photo is from my second attempt. What is going wrong here? I only have enough materials for 1 or 2 more runs, so i want to try and nip this in the bud. Any tips? Photos below:

0

Comments

/Chris

"You're not baking it long enough. A common issue is the overflow is cured, so you would assume the piece is cured…but the heat has not penetrated through the thickness of the stone. You should try 4.5 hrs at 180 degrees."

Hope this helps!

Matt