Servo to cable attachment.

in Animatronics

I'm looking for some input on a servo mounted push/pull type cable setup. I'm looking at having some pieces 3D printed unless I can find something premade. What types of setups are you using? Custom made, or off the shelf?

This will be for a standard RC servo, and I'll be using a nylon lined 5 mm casing with a 1.2 mm 7x7 cable, so fairly small and flexible. I had a couple printed before, but my design was too thin, and the alignment didn't come out right. The second design is thicker and I corrected the alignment. (Pictures below) Having pieces printed isn't really expensive, but it would be nice to have options. Let me know what you think, suggestions, questions, etc.

First design

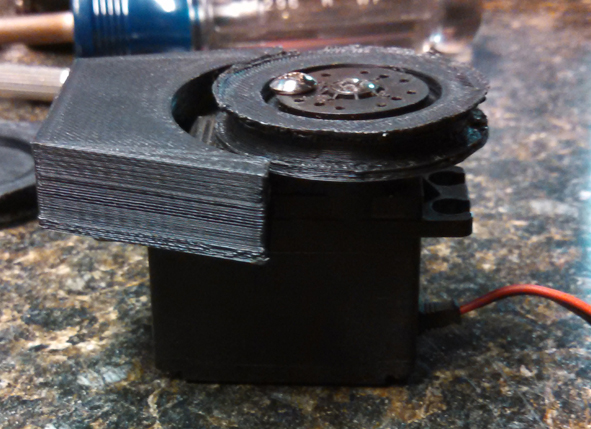

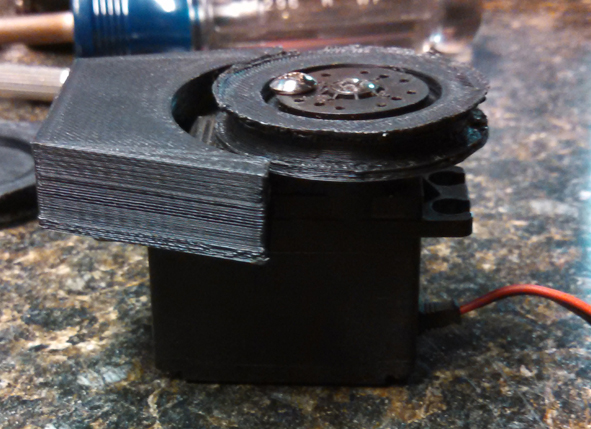

Second Design

This will be for a standard RC servo, and I'll be using a nylon lined 5 mm casing with a 1.2 mm 7x7 cable, so fairly small and flexible. I had a couple printed before, but my design was too thin, and the alignment didn't come out right. The second design is thicker and I corrected the alignment. (Pictures below) Having pieces printed isn't really expensive, but it would be nice to have options. Let me know what you think, suggestions, questions, etc.

First design

Second Design

1

Comments

What printer are you using? I'm actually waiting on a 4+ hour PLA print right now, part 4 of 16. Fun, but slow!

/Chris

I had them printed in ABS, and once I got the final design, I was going to sand, and then acetone smooth them. Nylon is a possibility though.

It might be possible to mold and cast them. Honestly never considered that. Might have to price it, and see which would be more cost efficient.

Oh, and my 4 hour print from my previous comment died just over 3 hours in. Nozzle clogged with PLA (finicky stuff)

Joel: If you are not ready to purchase a 3D printer you may be able to find some locally at a hacker/maker space or library that does a maker program. I'm actually a member of a LA hacker space called CRASH Space that has a few printers. I plan on purchasing one eventually, but I've yet to find the right printer.

/Chris

Best

Smooth On also has a new product called XTC-3D that you can brush onto printed parts to smooth out surfaces and hide print lines.

I'd love to see that tutorial!

/Chris

/Chris

Chris V. - Do you have any issues with the 'arms' flexing at the far end? I like the design. Mounting might be easier with this style also, if someone is looking to make a servo bank.

Thanks for the responses! Nice to be able to bounce ideas off people.